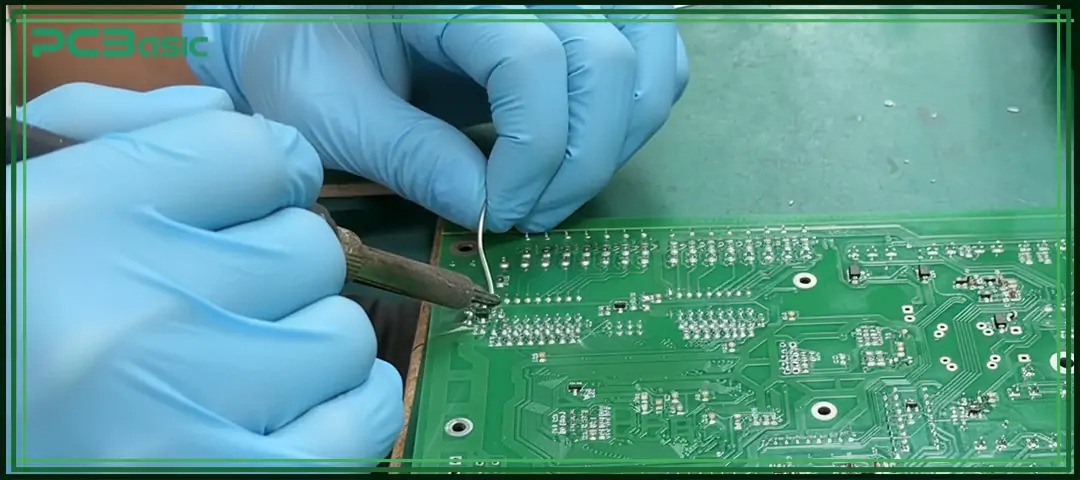

PCBasic Lead Free PCB Assembly Building Reliable and RoHS-Compliant Electronics

Selecting the right PCBA manufacturer is a critical decision for companies developing modern electronic products. As environmental regulations tighten and product reliability requirements increase, lead-free PCB assembly has become a standard rather than an option. PCBasic delivers professional lead-free PCB assembly services designed to meet global compliance requirements while maintaining consistent quality, process stability, and long-term reliability for customers worldwide.

Understanding Lead-Free PCB Assembly

Lead-free PCB assembly refers to the process of assembling printed circuit boards using solder materials and components that do not contain lead. This approach is essential for meeting RoHS and similar environmental regulations that restrict hazardous substances in electronic products.

Unlike traditional tin-lead solder, lead-free solder alloys are typically based on tin with added silver or copper. These materials require tighter process control and higher reflow temperatures, making manufacturing experience and equipment capability especially important.

Why Lead-Free Assembly Is Now the Industry Standard

The shift toward lead-free PCB assembly is driven by more than regulatory pressure. It reflects a broader transformation in electronics manufacturing:

Global Market Access

- Lead-free assembly allows products to be sold in regions with strict environmental requirements, including Europe and many international markets.

Environmental Responsibility

- Eliminating lead reduces environmental pollution and improves workplace safety throughout the manufacturing and recycling lifecycle.

Product Longevity and Brand Trust

- Manufacturers that adopt lead-free processes demonstrate long-term commitment to sustainability and quality, strengthening customer confidence.

Technical Challenges of Lead-Free PCB Assembly

Lead-free assembly introduces several technical challenges that must be address through proper engineering control:

Higher Reflow Temperatures

- Lead-free solder requires higher peak temperatures, which places greater stress on PCB materials and components.

Thermal Profile Optimization

- Improper temperature control can lead to defects such as insufficient wetting, solder voids, or component damage.

Process Stability

- Consistency across solder paste printing, placement accuracy, and reflow is essential to maintain high yield rates.

These challenges highlight why lead-free PCB assembly should only be handled by experienced manufacturers with mature process control systems.

PCBasic’s Lead-Free PCB Assembly Capabilities

PCBasic operates dedicated lead-free PCB assembly lines to ensure full compliance and eliminate the risk of cross-contamination from leaded materials. Every stage of production is designed around lead-free process requirements.

Key capabilities include:

Strict Material Control

- All solder pastes, components, and surface finishes are verified to meet lead-free standards before entering production.

Optimized SMT and Through-Hole Assembly

- Assembly parameters are carefully adjusted for lead-free solder behavior, ensuring stable solder joints and consistent results.

Advanced Inspection and Testing

- Automated optical inspection, X-ray inspection, and electrical testing are applied to detect defects and confirm assembly quality.

Process Traceability and Quality Control

- Each order is monitored throughout production to maintain repeatability and meet customer-specific reliability expectations.

Applications That Benefit from Lead-Free PCBA

Lead-free PCB assembly is widely used across multiple industries, including:

- Consumer electronics

- Industrial control systems

- Automotive electronics

- Medical devices

- LED lighting and power modules

In these applications, compliance, reliability, and long-term performance are equally important.

Lead-Free Assembly vs. Traditional Leaded Assembly

While leaded solder offers lower melting temperatures and easier processing, it is no longer suitable for most commercial products. Lead-free assembly, although more demanding from a manufacturing perspective, provides a safer and more future-proof solution that aligns with global standards.

When executed correctly, lead-free solder joints can deliver excellent mechanical strength, thermal resistance, and electrical performance.

Conclusion

Lead-free PCB assembly has become a fundamental requirement for modern electronics manufacturing. It demands precise process control, experienced engineering, and reliable quality systems. With its dedicated lead-free production lines and comprehensive assembly capabilities, PCBasic supports customers in building compliant, high-quality PCBAs that meet both regulatory and performance expectations.

Disclaimer

The information provided in this article is for general informational purposes only and does not constitute professional, legal, or regulatory advice. While PCBasic strives to ensure the accuracy and reliability of the content, readers should independently verify all information regarding lead-free PCB assembly, RoHS compliance, and other technical or regulatory requirements. PCBasic does not guarantee specific results, compliance outcomes, or product performance, and assumes no liability for any errors, omissions, or decisions made based on this article. For detailed guidance on PCB assembly, regulatory compliance. Technical processes, consulting qualified engineers or regulatory experts is recommended.