Enhancing Manufacturing Quality with Mobile Scanning Technology

In modern manufacturing, quality control is paramount. Factories manage countless components to assemble products, where tracking each part is crucial for success. Barcodes have become essential for this process, providing a digital identity for every item from its arrival to final assembly. Integrating mobile scanning applications into this workflow is transforming production quality assurance, defect tracking, and process validation.

The Role of Mobile Scanning in Quality Assurance

Mobile scanning applications empower plant employees to maintain high quality standards directly on the production floor. By scanning a barcode with a smart device, workers can instantly access a wealth of information. This includes part specifications, production history, and its intended destination within the facility.

This rapid data access is fundamental to quality assurance (QA). A parts tracking app facilitates several key QA functions:

- Part Identification: Instantly confirms the identity and specifications of a component.

- Check-ins: Logs the part’s current location and the employee handling it.

- Accessing History: Reviews past users and any notes or issues associated with the part.

- Change Requests: Allows operators to request modifications or flag parts for review.

Streamlining Defect Tracking and Process Validation

Mobile scanning is a powerful tool for identifying and documenting issues in real-time. It moves quality control from a reactive to a proactive model, ensuring processes are followed correctly and defects are caught early.

Real-Time Defect Reporting

When an employee discovers a flaw during assembly, they can scan the part’s barcode and immediately report the defect through the mobile application. This creates an instant digital record linked to the specific component. The information is then available to quality managers and other stakeholders, enabling swift action and preventing defective parts from moving further down the line.

Enhanced Process Verification

Process validation ensures that every step of assembly is performe correctly. Mobile scanning enforces this by requiring operators to scan components before they are install. The system can verify that the correct part is being use for a specific assembly, preventing costly errors that might otherwise go unnoticed until final inspection. This step-by-step verification builds quality directly into the manufacturing process.

Overcoming Scanning Challenges in Manufacturing

Manufacturing environments present unique challenges for scanning technology. Production floors can have varied lighting, and parts are often exposed to wear and tear. Modern mobile scanning solutions are engineered to overcome these obstacles.

Advanced scanning software can read barcodes under difficult conditions. This includes:

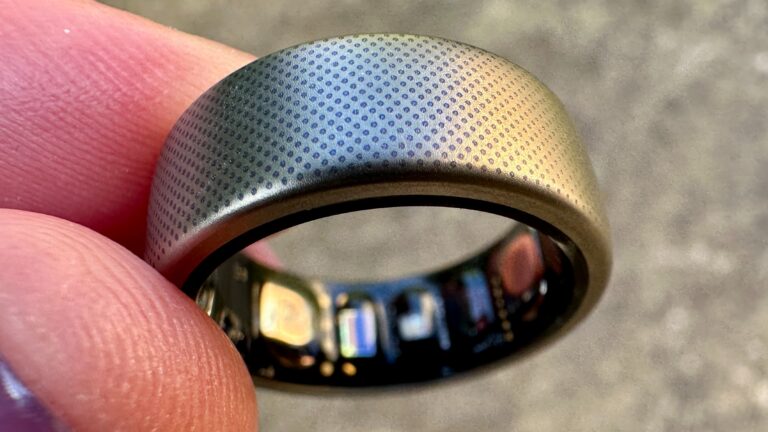

- Small or Damaged Barcodes: Sophisticated algorithms can decode tiny micro-Datamatrix codes etched on small components or read barcodes that are partially damaged or worn.

- Varied Lighting: Scanning performance remains reliable in both dimly lit warehouses and brightly lit production areas, minimizing errors.

- High-Speed Operations: Fast scanning capabilities keep pace with efficient workflows, preventing delays.

- Awkward Angles: Employees can capture data from difficult angles and distances, improving ergonomics in tight spaces.

The Shift to Mobile Devices for Scanning

The industry is moving from expensive, dedicated handheld scanners toward more versatile mobile technology. This shift is driven by cost savings, ease of use, and the advanced features offered by modern devices. Companies can implement scanning capabilities across their workforce without a massive hardware investment.

Cost-Effectiveness and Accessibility

Smartphones are considerably less expensive than industrial-grade scanners. By implementing a Bring-Your-Own-Device (BYOD) policy, companies can further reduce hardware costs. Even when purchasing devices, the maintenance and repair costs for smartphones are typically lower. Making scanning accessible to more employees eliminates the bottleneck of sharing a limited number of dedicated scanners, boosting overall productivity.

Advanced Features for Enhanced Productivity

Modern mobile devices offer features beyond simple scanning. Augmented reality (AR) overlays can provide real-time visual guidance, displaying step-by-step instructions or highlighting the exact part to be picked. These advanced features are available on standard smartphones and purpose-built devices like a mobile computer scanner, which are specifically designed for industrial use. This intuitive interaction speeds up adoption and enhances accuracy.

Ensuring Device Durability and Security

A primary concern with using consumer-grade devices in factories is durability. To address this, smartphones can be outfitted with ruggedized cases that meet industrial standards. These cases provide protection against drops, water, dust, and dirt, ensuring the devices can withstand harsh conditions. For BYOD programs, clear policies and robust security measures like data encryption and access controls are essential. These protocols safeguard sensitive company data while maintaining employee privacy.

Disclaimer

The information provided in this article, Enhancing Manufacturing Quality with Mobile Scanning Technology, is intended for general informational purposes only. While the content outlines best practices and potential benefits of using mobile scanning technology in manufacturing environments, it does not constitute professional advice or guarantee specific outcomes. Companies considering the implementation of mobile scanning solutions should conduct their own assessments, consult relevant experts, and evaluate their unique operational requirements before adopting any technology or process changes. The author and publisher are not responsible for any decisions, actions, or results arising from the use of the information presented in this article.